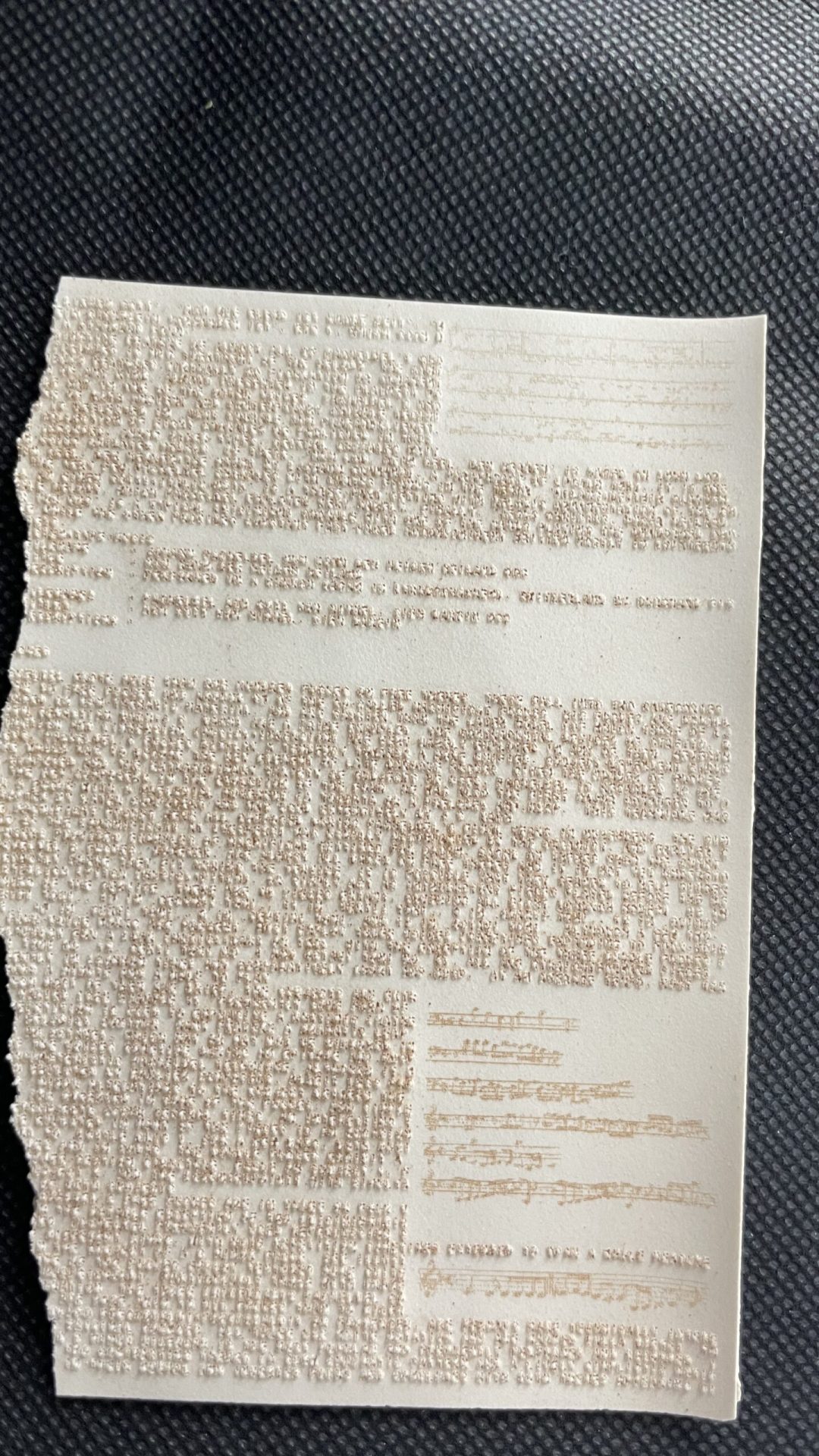

For our clay tablets we either use clay that was developed by a team of professors and students at TH Nuremberg. The team under Prof. Raab and Mr. Thürach found and tested a type of clay that after being customized and heat processed, can last for eternity. The clay consists of a base clay mixed with different components.

We are currently undergoing experiments to reach the same durability with clay tablets made out of thin porcellain foil.

The faculty of materials engineering prides itself with developing and testing the most innovative and durable materials for use in both research and industry. That’s why we strive to reach maximum longevity and durability with our tablets.

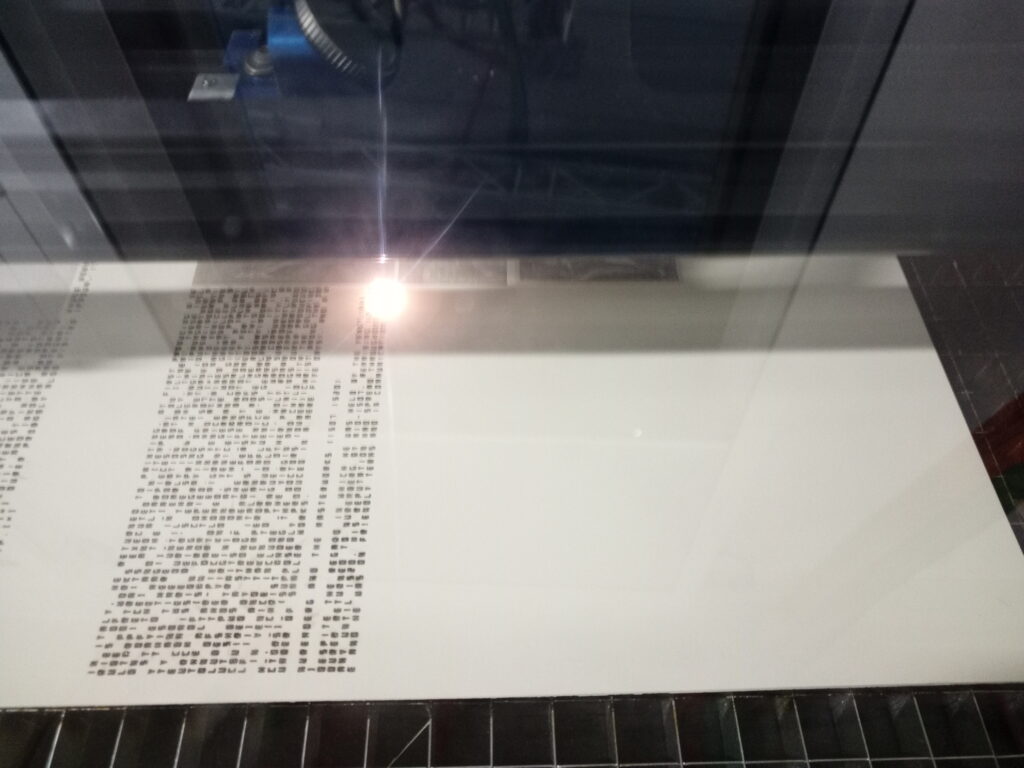

We work with different production methods for different types of clay. Our porcellain clay tablets are laser cut on our faculty’s laser cutter whereas in the past, our thicker clay tablets were also lasered or mill-cut by the CNC_3018Pro.

We try to make our production methods as efficient as possible. That’s why we strive to improve our laser-cutting process to ensure better readability, image reproduction and longevity of our clay tablets. Using the laser cuter is also much safer and less error-prone than using the mill cutter.

Our kiln is what finalizes the durability of our clay tablets. It heats the clay to 1000° Celsius which stops the clay from being brittle and suspectible to enviromental damage.

We hope that one day, after many lifetimes, a team of researchers can find our safely stored clay tablets perfectly preserved and decipher the most important knowledge about our generation.

Run our code on the laser cutter.

Bake finished clay tablet.

Another clay tablet saved for our posterity!